With the somewhat

recent advent of computers in our field, we are now able to diagnose many

problems through what I call “Tension Analysis”. Through Tension Analysis, we

can measure the tension on a piano and quickly identify problems that may have

been missed on a physical inspection. Some of these things include identifying

problem changes in humidity, cracked plates and or struts, separated or cracked

pin blocks, loose tuning pins, problems in string stability,

etc…

Tension Analysis can be done the first time a technician sees the piano. It can head off years of dissatisfaction with a piano by identifying potential or current problems. It enables the owner to take care of a problem before they put money into a piano and are dissatisfied with the result. It is also extremely beneficial for the prospective buyer.

There are as many recommendations for these type of problems as there are

problems, there is however a more common problem called

stability.

Stability

Stability deals with how well a piano holds it's tuning. Manufacturers in

general recommend tuning a piano twice a year (every six months) to keep it in

top shape. This allows the piano to stay in tune and the player is able to get

the most enjoyment out of the piano. It also will train a child's ear to hear

music the way it is supposed to sound, this enables them to develop

discriminating taste in music.

When a piano is new, there is a "break-in-period" where all the separate

components of a piano shift and get used to each other under around 50,000

pounds of tension. A new piano needs more tunings the first year to reach that

stabilization that will allow them to hold a tune for a normal 6 month interval

of tuning. For a new piano, most manufacturers recommend four tunings the first

year in this break-in period. Most dealers forget to tell people this.

Click here to read what Manufacturers have to say in their own words.

There are two sub-headings under stability that I want to touch on as they

are the most common. They are:

1. The need for Humidity Control

2. Identifying a

piano that won't hold a tune

The need for Humidity Control

For brevity on this web page, I will publish these pre-existing links.

An example of low humidity

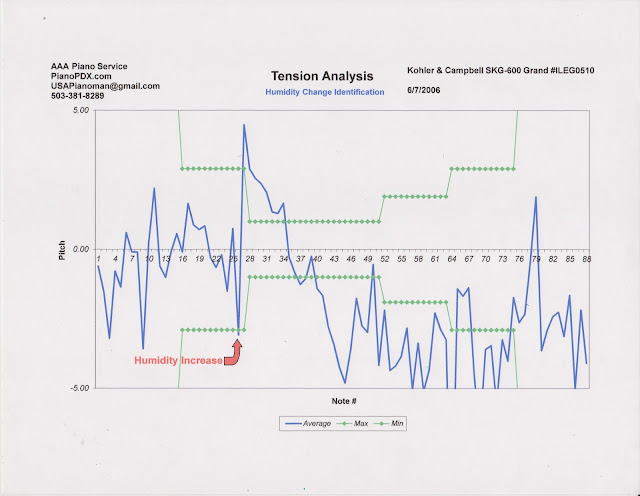

I was called to a recording studio where they had reported the piano going

wildly out of tune. From servicing the piano before, I knew this piano had a problem

with humidity fluxing beyond what the piano could cope with. I had installed

an electronic humidity control system to solve the problem, but the piano didn't do what I expected. The owner called me because they thought the piano was way out of tune.

I had only tuned this piano 4 months ago. I wanted to know why the piano

did not stay in tune. This is the graph I got from the Tension Analysis.

The treble bridge is located towards the center of the soundboard and moves more than the bass bridge (which is close to the side of the piano) where the soundboard swells or shrinks less when humidity changes.

The piano is a complex feat of engineering and physics. Yet for the most part, pianos are an assembly line item. Manufacturers have a bottom line where they may only spend a certain amount of time on a piano and still make a profit.

There is a point where the piano is "good enough" say for 90% of the public and they send it out the door. Even then, the uniformity between pianos can vary widely, even between pianos with adjacent serial numbers.

Variations can be natural or man-made. Being made of components we find in nature...i.e. wood, felt, leather, etc... no two pianos will be alike. Changes in environment will have an effect on the touch, tone and stability of the instrument. Minute changes in manufacturing processes and machining would be examples of man-made variations.

It is because of these reasons, all pianos need to be "prepped" in the store before the sale, or afterwards in the home to bring out the best performance in the instrument. This is where the technician comes in. If the store technician is to bring the most out in the instrument, he must be allowed to "prep" the piano and get it ready for sale.

I have found the problem of string stability in every name brand I have encountered in the last nine years. Sadly enough, not much attention is paid to the area of seating strings, but this is the main cause that some pianos do not hold a tune. In the past, some of the fine technicians recognized this problem and an attempt they called "Tapping Down the Strings" was tried with a little bit of success. They knew it helped, even though it improved the stability, it was not good enough and the piano was particulary unstable for the first few months.

The Solution

In mid 2004 I took this problem head on. After tuning pianos by ear for over 10 years, I started working with an electronic tuning device that hears with about 100 times more accuracy that we can with our ears. It opened up new vistas in piano technology for me. The computer gave me more feedback about what was happening to the piano than I could detect or measure by ear. I could visually see what was going on with the piano and actually graph what I now call string instability. This is a graph of a piano's tension after tuning it 4 times the first year (as the manufacturer recommended) and even installing a humidity control system.

This next graph shows what happens to the individual tension of all the strings. When the tension on every other string drops, the tension is taken up by and increased on the "skipped" strings. It would create a vast amount of trauma change in tension if this were not allowed to happen. This way the piano stays in tune immediately instead of being very unstable the following year. This is the difference between the "Traditional Tap Down Procedure" and what we offer.

Notice the big drop in tension

between the bass and treble bridges. The big change in tension between these

bridges is the greatest indicator of humidity fluxing. The reason for this is because of

the location of the bridges on the soundboard.

The soundboard is the big

expanse of wood underneath the strings. It acts as an amplifier for sound.

Because the soundboard is made of wood, it expands and contracts with the changes

in moisture in the surrounding air. As the amount of moisture in the air changes, so does the soundboard.

The treble bridge is located towards the center of the soundboard and moves more than the bass bridge (which is close to the side of the piano) where the soundboard swells or shrinks less when humidity changes.

I mentioned before that I had

installed a humidity control system in this piano that would effectively

compensate for the changes in humidity. The system has a flashing light and a

beeper that lets you know when to add water to the reservoir as the piano's request.

The client had me remove the beeper when I installed the system because they

did not like the sound of the beeper.

Solution

When I arrived, the system was

completely out of water. The client did not notice the flashing light. The

piano had dried out and the soundboard had shrunk up causing the strings to

drop in tension.

I ended up reinstalling the beeper,

watering the piano and rescheduling the tuning for when the piano recovered.

An example of high humidity

My Piano Won't Hold a Tune!

The piano is a complex feat of engineering and physics. Yet for the most part, pianos are an assembly line item. Manufacturers have a bottom line where they may only spend a certain amount of time on a piano and still make a profit.

There is a point where the piano is "good enough" say for 90% of the public and they send it out the door. Even then, the uniformity between pianos can vary widely, even between pianos with adjacent serial numbers.

Variations can be natural or man-made. Being made of components we find in nature...i.e. wood, felt, leather, etc... no two pianos will be alike. Changes in environment will have an effect on the touch, tone and stability of the instrument. Minute changes in manufacturing processes and machining would be examples of man-made variations.

It is because of these reasons, all pianos need to be "prepped" in the store before the sale, or afterwards in the home to bring out the best performance in the instrument. This is where the technician comes in. If the store technician is to bring the most out in the instrument, he must be allowed to "prep" the piano and get it ready for sale.

I have found the problem of string stability in every name brand I have encountered in the last nine years. Sadly enough, not much attention is paid to the area of seating strings, but this is the main cause that some pianos do not hold a tune. In the past, some of the fine technicians recognized this problem and an attempt they called "Tapping Down the Strings" was tried with a little bit of success. They knew it helped, even though it improved the stability, it was not good enough and the piano was particulary unstable for the first few months.

The Solution

In mid 2004 I took this problem head on. After tuning pianos by ear for over 10 years, I started working with an electronic tuning device that hears with about 100 times more accuracy that we can with our ears. It opened up new vistas in piano technology for me. The computer gave me more feedback about what was happening to the piano than I could detect or measure by ear. I could visually see what was going on with the piano and actually graph what I now call string instability. This is a graph of a piano's tension after tuning it 4 times the first year (as the manufacturer recommended) and even installing a humidity control system.

"Realistically, a pitch

difference of a few percent can usually be accommodated successfully during

tuning." This is a separate procedure from tuning and therefore is extra

money. You can see where it would be frustrating having to pay extra on tuning

when the piano should be more stable.

Click here for detailed information on pitch raising

The key to identifying string

instability on a graph like this is noticing the large changes in pitch

between adjacent notes. A physical test can be performed also for

verification.

Since a string is under tension,

seating a string properly so that it cannot shift or move in certain places

will change the overall tension of that string. The following is a photograph

of strings that were not seated properly against the plate at the hitch pin.

Seating the string by tapping it down against the plate will cause the string

under tension to decrease in tension and become flat in pitch. This change in

pitch can be measured. The overall change that results will be the amount of

instability removed from the piano.

There are a number of places that need to be adjusted when seating the strings properly. There is also a certain procedure that must be followed to get results that are expotentially improved from the old "Tap Down Procedure" that technicians have done for years. These following keys are the critical issues I have developed through computer aided research in the last two years.

Keys to Stability

1. Change all parts of the string that will move.

2. Make the string travel in a "bee line" (in the shortest possible 3 dimensional route). To make a bee-line, all wire needs to be "helped" when it takes a bend. Whether the bend is around a hitch pin, bridge pin, or bearing point, whenever the angle of the string changes, there will be slack that can be removed. Remember helping a wire bend can be in two different dimensions at one time.

3. Cause the least amount of trauma to the overall tension of the piano by doing half of the piano at a time. This means changing every other string on the piano and then bringing those strings back up to tension with a pitch raise.

4. Stretch the plain wire strings with a string stretcher. Almost 50% of the total change of a string comes from stretching it. We don't stretch wound bass strings because it messes up the coils.

Keys to Stability

1. Change all parts of the string that will move.

2. Make the string travel in a "bee line" (in the shortest possible 3 dimensional route). To make a bee-line, all wire needs to be "helped" when it takes a bend. Whether the bend is around a hitch pin, bridge pin, or bearing point, whenever the angle of the string changes, there will be slack that can be removed. Remember helping a wire bend can be in two different dimensions at one time.

3. Cause the least amount of trauma to the overall tension of the piano by doing half of the piano at a time. This means changing every other string on the piano and then bringing those strings back up to tension with a pitch raise.

4. Stretch the plain wire strings with a string stretcher. Almost 50% of the total change of a string comes from stretching it. We don't stretch wound bass strings because it messes up the coils.

The next 4 graphs are from the same piano at various stages of the process.

This next graph shows what happens to the individual tension of all the strings. When the tension on every other string drops, the tension is taken up by and increased on the "skipped" strings. It would create a vast amount of trauma change in tension if this were not allowed to happen. This way the piano stays in tune immediately instead of being very unstable the following year. This is the difference between the "Traditional Tap Down Procedure" and what we offer.

Even though there are a few individual notes that are outside a 5 cent range, this next chart shows a very desirable place to start a fine tuning. Most of the readings are even within the target range. We changed some strings almost 375 cents and in two passes (pitch raises) they are ready for a fine tuning. That’s impressive because a piano can normally accomodate only about a 4% change in tension. This process exceeds that.

The last graph shows the result of the fine tuning. All pitches are within my target range and additionally within +/- 1 cent. This is fantastic for a brand new piano. Things will only get better with time as the piano goes through it's "new piano break-in period".

Here is some video of the process of seating strings to create tuning stability. Notice how the string which is under tension changes when seated properly.

Other videos:

Single Tied vs Shared Strings AND Reduction Of False Beats

.jpeg)

.jpeg)

.jpeg)

No comments:

Post a Comment